This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

The Battery Intelligence Platform: Transforming stationary energy storage and electric vehicles.

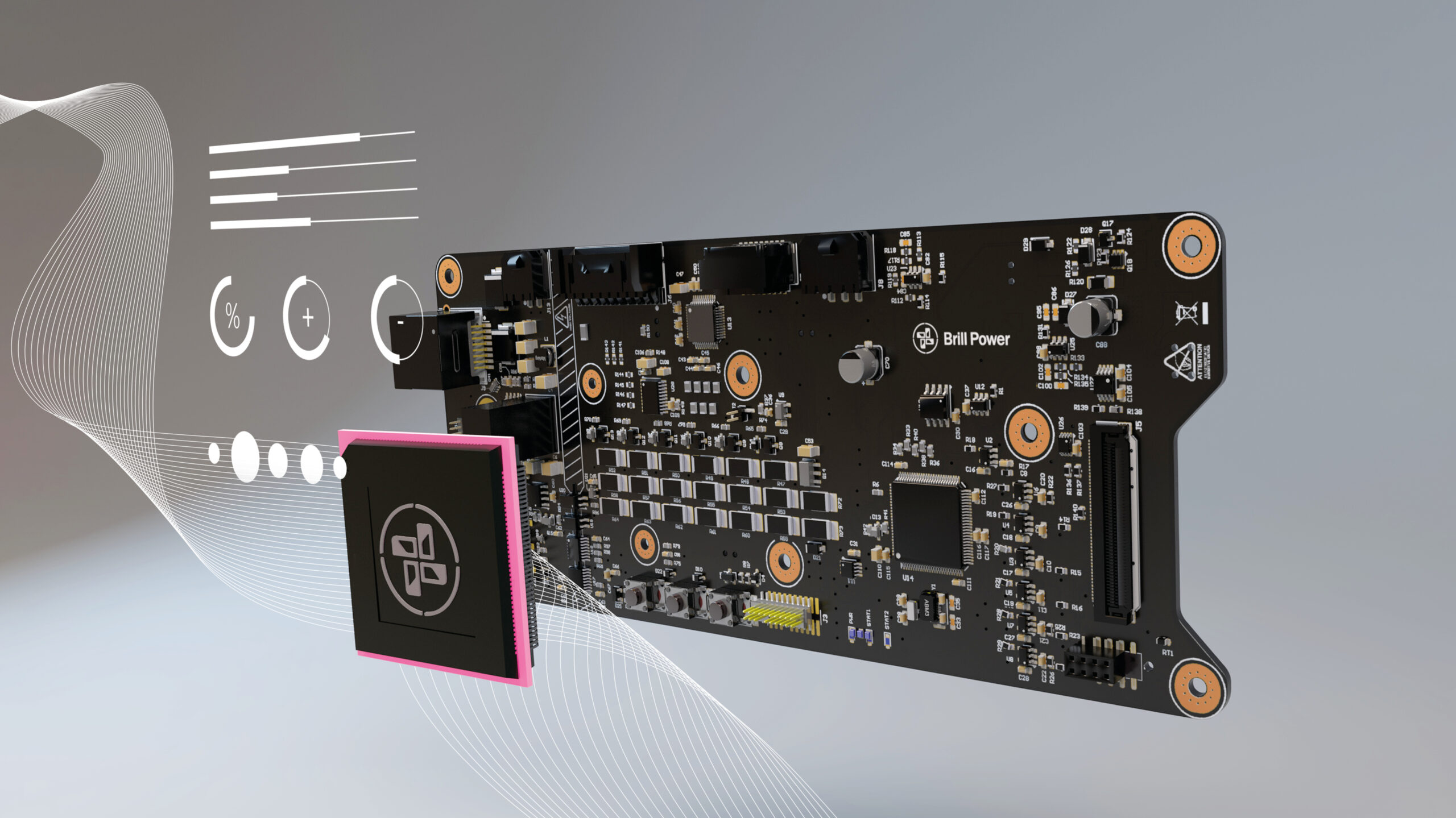

BrillCore

The BrillCore utilizes the patented active loading technology to enable benefits such as up to 60% longer battery lifetime, up to 46% more energy from aged batteries, faster charging rates, and improved safety. It is scalable to any system and integrates DC/DC conversion.

BrillOS

BrillOS is the world’s first future-proof, highly portable, chemistry-agnostic Operating System for batteries, with high precision monitoring algorithms, customizable settings, and over-the-air updates.

BrillAnalytics

BrillAnalytics delivers end-to-end data and insights for safe and optimal battery use.

Unique Capabilities

Our unique patented active loading technology creates maximal lifetime, performance, and reliability.

Proactive protection using active loading, with module-level protection.

High-resolution sensor data, SOC, SOH, and SOF with end-to-end monitoring via our analytics platform.

The BrillCore includes a fully integrated DC/ DC converter.